Revolutionizing Calcium Hydroxide Production: The Cronus Advantage in Limestone Machinery

Cronus is one of the leading calcium hydroxide equipment manufacturers in China, focusing on the research and development and manufacturing of calcium hydroxide production lines for many years. Its equipment is known for its high efficiency, intelligence and environmental protection, and is widely used in building materials, environmental protection, chemical industry, food industry and other fields.

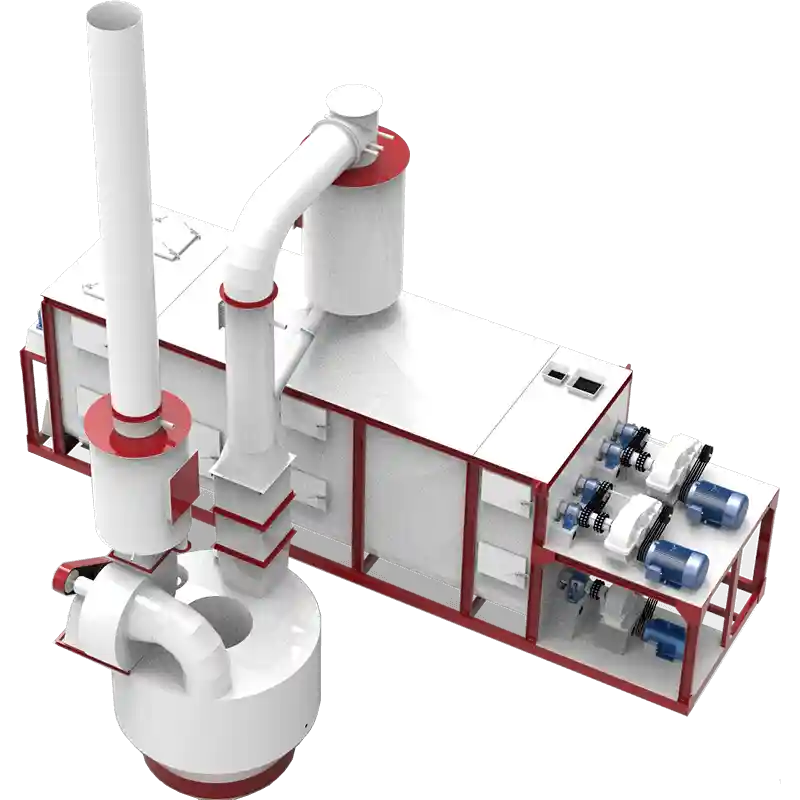

Cronus calcium hydroxide production line adopts advanced technology and special equipment

The raw material section uses jaw crusher for coarse crushing and hammer crusher for fine crushing to prepare 20-50mm limestone; the calcination section uses energy-saving rotary kiln (Φ2.5-4.8m) to decompose limestone at high temperature, and cooperates with vertical preheater to recover waste heat.

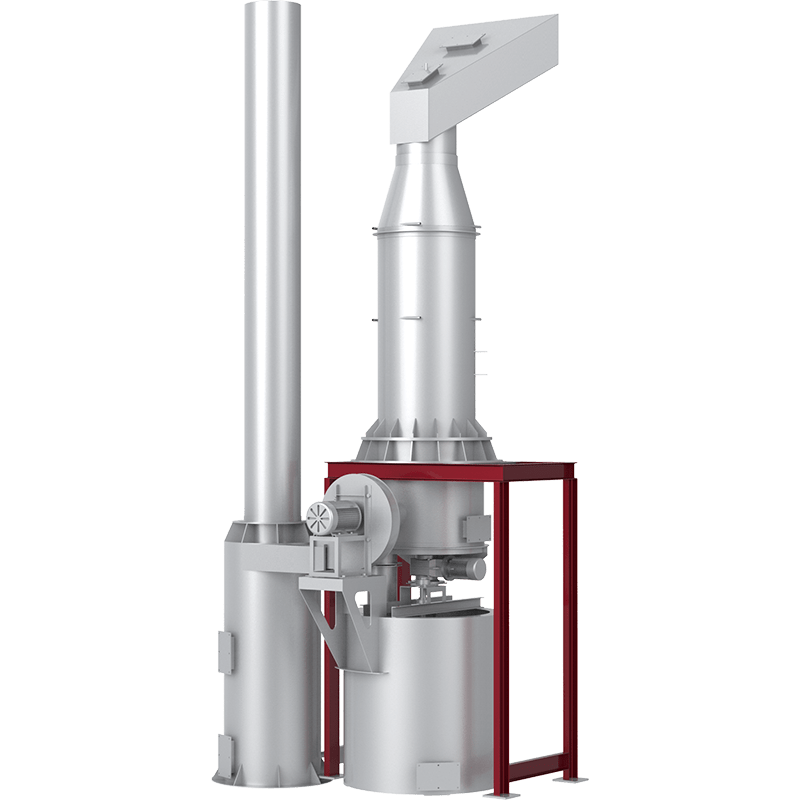

The digestion section uses pulse digester to achieve precise reaction between CaO and water; the refining section uses QF airflow classifier to adjust the fineness (200-1000 mesh).

The drying and packaging section uses flash dryer for dehydration and fully automatic packaging machine for sealing. The whole process is controlled by PLC, with high purity (CaCO₃≥95%), low energy consumption and environmental protection characteristics.

Cronus calcium hydroxide production line core advantages

1. High Efficiency and Energy Saving

- Waste Heat Recovery: Kiln exhaust gases preheat raw materials to reduce energy consumption.

- Rapid Hydration: Patented chain-agitated hydrators heat water to 80°C within 5 minutes, accelerating reaction speed and increasing capacity (single unit output up to 30t/h).

2. Intelligent and Automated Operation

- PLC Control System: Fully automated control of calcination temperature, water volume, and classification precision ensures product stability.

- Online Monitoring: Modern moisture analyzers provide real-time monitoring to ensure product moisture content ≤2%.

3. Environmental Compliance

- Dual Dust Removal: Pulse bag dust collectors + water mist systems ensure dust emissions ≤5mg/m³, exceeding national standards.

- Water Recycling: Hydration process water is recycled to minimize resource waste.

4. Flexible Configuration

- Modular Design: Production lines with annual capacities of 10,000-300,000 tons can be customized to meet different scale requirements.

- Process Options: Both dry and wet processes available to meet industrial-grade, food-grade, and other standards.

Application areas

Environmental protection industry: wastewater treatment, flue gas desulfurization (SO₂ emission reduction).

Chemical industry: alkali production, bleaching powder, PVC production.

Construction industry: mortar, coating, putty powder.

Food industry: food-grade calcium hydroxide (requires additional purification process).

Cronus’ calcium hydroxide production lines stand out for their efficiency, intelligence, and environmental performance, making them the preferred choice for numerous domestic and international enterprises. Whether for large-scale industrial projects or smaller production lines, Cronus offers customized solutions and turnkey project services. For detailed technical proposals or equipment specifications, please contact Cronus directly for the latest documentation or to arrange a factory visit.